Condition:New

- Description

- Specifications

- Documents

Keithley 2450 SourceMeter SMU Instrument

Key Features

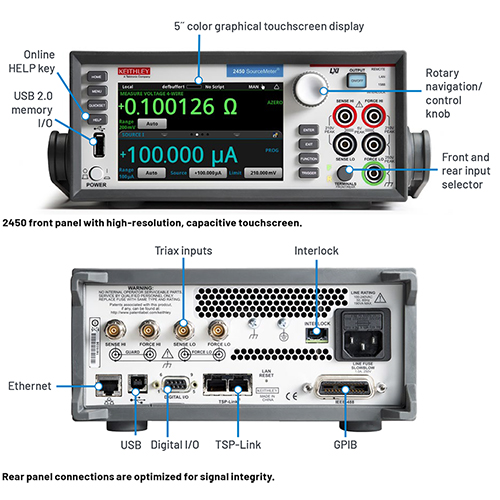

5-inch high‑resolution capacitive touchscreen GUI for intuitive control and reduced learning curve.

0.012% basic measure accuracy with 6.5‑digit resolution for precise sourcing and measurement.

Enhanced low‑level performance with 20 mV and 10 nA source/measure ranges.

Four-quadrant source and sink operation up to 200 V, 1 A, 20 W.

All‑in‑one instrument: precision power supply, DMM, electronic load, current source, and trigger controller.

Quickset modes for fast configuration of common SMU tasks.

Built‑in plotting, charting, and data export directly from the front panel.

TSP® scripting + TSP‑Link® for scalable multi‑instrument automation (up to 32 units).

Multiple connectivity options: USB, GPIB, Ethernet/LXI, digital I/O, rear triax.

KickStart™ software compatibility for rapid I‑V characterization.

Optional I‑V Tracer app enabling intuitive curve tracing.

The 2450, Keithley’s next-generation SourceMeter source measure unit (SMU), a 200V, 1A, 20W instrument, truly brings Ohm’s law (current, voltage, and resistance) testing right to your fingertips. Its innovative graphical user interface (GUI) and advanced, capacitive touchscreen technology allow intuitive usage and minimize the learning curve to enable engineers and scientists to learn faster, work smarter, and invent easier.

The 2450 is the SMU for everyone: a versatile instrument, particularly well-suited for characterizing modern scaled semiconductors, nano-scale devices and materials, organic semiconductors, printed electronics, and other small-geometry and low-power devices. All this combined with Keithley SMU precision and accuracy allows users to Touch, Test, Invent® with the new favorite go-to instrument in the lab for years to come.

Technical Highlights

Performance & Ranges

Voltage: 20 mV to 200 V ranges

Current: 10 nA to 1 A ranges

Resistance measurements up to 200 MΩ+ (via source‑voltage or source‑current techniques)

Noise performance: ~2 mV RMS typical on voltage source (10 Hz–1 MHz)

Speed & Productivity

Up to >3000 readings/second in high‑speed modes

250,000‑point buffer for large data sets and sweeps

User Interface

Touch‑driven menus reduce configuration steps by up to 50%

Graphical sweep plots, tables, and real‑time charting on screen

Connectivity

Rear: Triax, USB‑B, Ethernet/LXI, GPIB, digital I/O

Front: USB‑A for scripts, data storage, and updates

TSP‑Link for multi‑instrument synchronization and parallel testing

Applications

The 2450 is optimized for electrical characterization and functional testing in:

Nanomaterials & Nanodevices

Graphene, CNTs, nanowires, low‑power nanostructures

Semiconductors

Wafer‑level tests, thin films, small‑signal BJTs, FETs

Organic / Printed Electronics

E‑inks, OLED/AMOLED, flexible electronics

Energy & Optoelectronics

LEDs, photovoltaic cells, batteries, and electrochemical systems

General Components

Diodes, resistors, sensors, zener diodes, HDD heads

Material Characterization

Resistivity, Hall measurements, high‑ohmic components (with triax)

In The Box

2450 SourceMeter Instrument

Power Line Cord

Test Leads

USB Cable

Ethernet/TSP-Link Cable

Safety Interlock Mating Connector/Adapter

Quick Start Guide

TSP Toolkit Software

KickStart Startup Software

LabVIEW and IVI Drivers

FAQ: Frequently Asked Question

1) How do I configure the Keithley 2450 to source voltage and measure current (or vice versa)?

On the touchscreen, choose Source Function (Voltage or Current) and Measure Function (the complementary parameter). Set the source level, compliance limit (current limit when sourcing voltage, or voltage limit when sourcing current), and an appropriate measurement range. Use Quickset presets to speed up common tasks, then view results on the built‑in plot/table screens. This workflow enables safe, repeatable I‑V characterization for diodes, transistors, sensors, materials, and more.

2) What’s the difference between 2‑wire and 4‑wire (Kelvin) measurements, and when should I use each?

2‑wire: The same leads carry source and measurement signals. It’s fast and fine for general‑purpose work, but lead resistance can add error—especially at low resistance or low voltage.

4‑wire (Kelvin): Separate force and sense leads measure voltage directly at the DUT terminals, effectively eliminating lead resistance error.

Recommendation: Use 2‑wire for routine measurements; switch to 4‑wire for high‑precision, low‑ohmic, or low‑level measurements (the 2450’s rear triax connections and sense terminals make this straightforward).

3) How can I automate measurements or remote‑control the Keithley 2450?

Choose from multiple paths:

No‑code control: Use KickStart™ to set up I‑V sweeps, log data, and export results without writing scripts.

Scripting on the instrument: Use TSP® (Test Script Processor) to run tests locally and scale to multi‑unit systems via TSP‑Link®.

Traditional remote control: Connect over USB, LAN (Ethernet/LXI), or GPIB and use SCPI (2400‑compatible) from environments like Python (PyVISA), LabVIEW, or MATLAB.

All approaches support high‑throughput workflows (e.g., automated sweeps, data logging, production test).